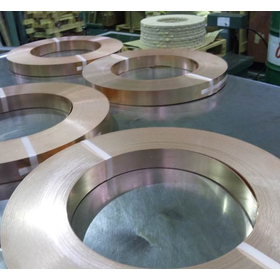

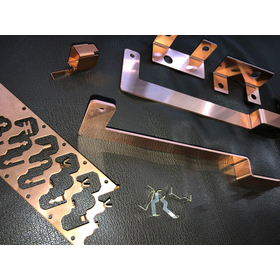

Also for prototyping busbars, terminals, and terminal materials! Coils, plates, and plating materials can be procured in necessary quantities when needed through our in-house inventory and procurement network.

Tatsumiya Metal's metal material sales can provide high-quality non-ferrous metal materials and plated materials with short delivery times, thanks to our extensive in-house inventory and slitting equipment.

Typically, the delivery time for standard material supply, such as coil materials, takes about one week to ten days. However, at Tatsumiya Metal, we maintain inventory and perform in-house processing, allowing us to ship on the same day as the order and deliver the next day at the earliest. (Note: The usual delivery time is 4 to 5 days.)

The minimum lot size for coil materials is usually 2 kg/mm. For prototypes, we can provide materials in units of a few centimeters, allowing us to respond to shipping needs based on application and urgency. We also quickly accommodate requests for prototype materials in sheet form.

This approach reduces inventory risk, enabling material supply only as needed when required.

**Features**

- Stock of various copper products and plated materials

- Support from in-house and external slitting facilities

- Through our supply network, we can provide and propose prototype materials in coil form and standard-sized sheets beyond our in-house inventory.

- We have established a supply system through a network with domestic and international copper product manufacturers.

Additionally, we can accommodate both prototypes and mass production of thick copper materials for busbars, which have seen increasing demand in recent years.

*For more details, please download the catalog or contact us.*

![Check the trends of the copper bullion market at a glance! Analysis! [Free graph available]](https://image.mono.ipros.com/public/product/image/9a9/2000242416/IPROS2235627367216692879.png?w=280&h=280)

![[Production examples] Machining of environmentally friendly materials such as lead-free brass.](https://image.mono.ipros.com/public/product/image/5bf/2000435380/IPROS11415096575018895330.JPG?w=280&h=280)